HM Parc Prison is a Category B men’s private prison and Young Offenders Institution, located in Bridgend, South Wales. Parc Prison is operated by G4S and is the only privately operated prison in Wales.

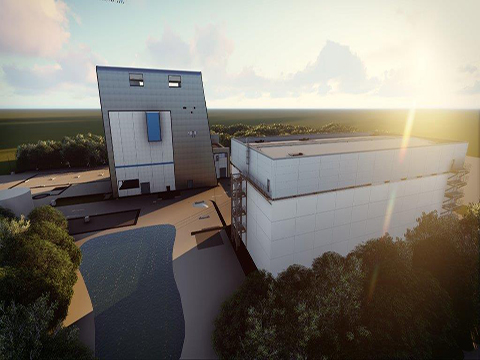

Parc Prison was the first prison in the UK to be built under the Government’s Private Finance Initiative in the 90’s. In 2013 further developments were required and working alongside main contractor Galliford Try on a new £30m scheme to create capacity for an additional 387 inmates, SES Engineering Services (SES) was asked to further develop the site comprising four key elements – a new gatehouse, visitor centre, prisoner block and a workshop.

SES used the latest manufacturing methods to drastically reduce commissioning time on its £7.7m MEP services project at HM Parc Prison by making extensive use of their industry-leading prefabrication factory, Prism.

Prism’s specialist team delivered a series of innovative offsite solutions which resulted in significantly reducing delivery timescales and carbon footprint as well as improving health and safety.

SES’ extensive brief saw the delivery and installation of 41 riser modules that spanned over three levels of the new building. The remit was to provide all of the MEP building services including domestic hot and cold water, electrical power and lighting, CCTV and the building management system, as well as generators, smoke ventilation, combined heat and power and air conditioning.

The new facilities opened in January 2015 and are now fully operational.

taken offsite by using Prism

M&E value

riser modules spanning over 3 levels

“SES Engineering Services’ experience in this sector has been invaluable, and they integrated with our delivery team to meet the project’s exacting standards and requirements.

“The modular solutions and offsite manufacturing utilised by Prism has proven to be an efficient method of construction which has helped to mitigate delivery risks and guarantee quality. When the design is properly considered in advance, this is a win-win construction method.”

Other Case Studies

The Defence and National Rehabilitation Centre (DNRC)

Handed over by Prince William, the Duke of Cambridge and Prime Minister, Theresa May in June 2018, the DNRC will be operated by the Ministry of Defence when it opens later this year.

Newcastle District Energy Centre

Supporting the city of Newcastle Upon Tyne in its endeavours to go carbon neutral by 2030, SES Engineering Services (SES) was directly appointed by Engie as main contractor to design and install complex MEP solutions on Newcastle District Energy Centre.

Teesside Energy Centre

SES Engineering Services (SES) was appointed to design, install and commission the mechanical, electrical and plumbing (MEP) services on Teesside Energy Centre which was constructed by a consortium between Lagan Construction and Babcock & Wilcox Vølund (BWV).