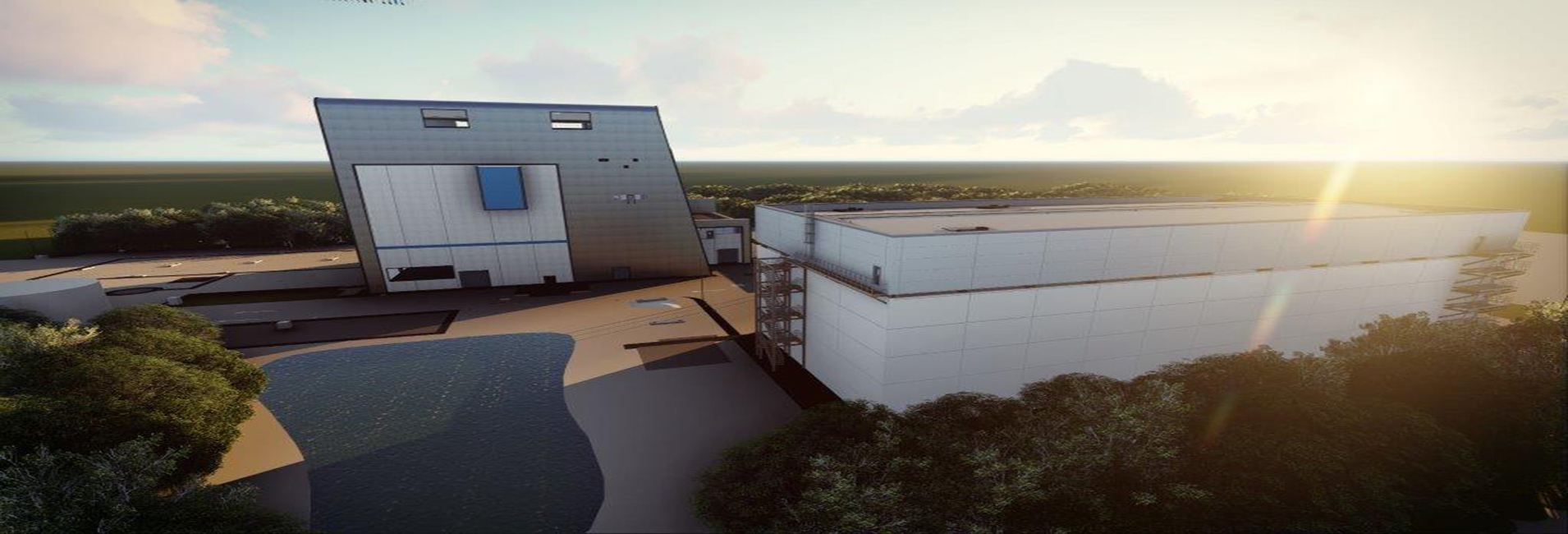

Teesside Energy Centre is a £160m energy from waste project which will generate 40MWe of electricity by using recycled wood chip as the fuel supply, the facility is capable of processing 250,000 tonnes of waste wood per annum, including contaminated wood, with no pre-treatment. SES Engineering Services (SES) was appointed to design, install and commission the mechanical, electrical and plumbing (MEP) services on this project which was constructed by a consortium between Lagan Construction and the Danish process supplier Babcock & Wilcox Vølund (BWV).

A key factor in the successful delivery of the project was the design of the MEP services directly into a centrally held 3D model thereby co-ordinating not only with the structural elements of the building itself, but with the process services package provided by BWV. This ensured a seamless integration of both the MEP and process services and structures into the facility.

SES’ scope included: External Lighting, Incoming Mains Cold/Fire Water Mains, Fire Tank and Pumps, Internal Lighting, CCTV, Fire Alarms, Containment, Small Power, Access Control, DDA, Sprinklers, Dry Risers, Mechanical Ventilation, Sanitary Ware, Domestic Water, Soil & Waste, Cooling, Gas Suppression, Water for Wash Down, Emergency Showers and Dust Suppression.

SES was also successful in securing the Margam Energy from Waste project in Port Talbot, which is the sister project to Teesside Energy Centre.

Other Case Studies

GSK Aseptic Manufacturing Facility - Q Block

SES worked to a detailed schedule of works to install all mechanical and electrical (M&E) building services, ensuring that there was minimum disruption to the live manufacturing site which completed in January 2020.

Barnsley Custody Suite

SES Engineering Services completed the £1.7m contract to deliver mechanical and electrical (M&E) services on South Yorkshire Police’s new state-of-the-art Barnsley Custody Suite.

Akzo Nobel ECG Building

SES was pleased to be appointed to work closely with construction, infrastructure and support services company Robertson CE on this important project, with responsibility for mechanical and electrical services.