saved by using Prism

test track

rail length for the factory

‘Excellent’

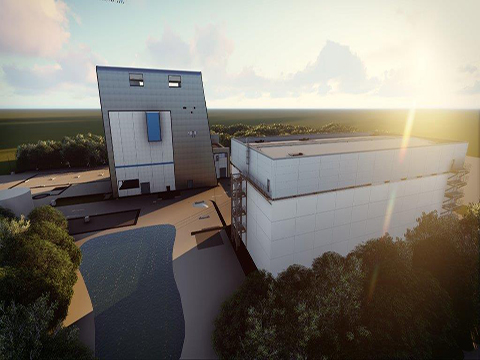

SES Engineering Services (SES) was appointed in November 2013 to design, build and fit out a brand new Rail Vehicle Manufacturing Facility in Newton Aycliffe, County Durham, for Hitachi Rail Europe. This 43,000m2 facility was Hitachi’s first in Europe and was a central part of an £82m investment to create a rail manufacturing centre of excellence in the North East of England.

Creating 730 permanent new local jobs and thousands more in the wider UK supply chain, the state-of-the-art facility at Newton Aycliffe has become Hitachi Rail’s primary European base for train manufacturing and assembly. It is the base for the manufacture of the new Great Western Main Line (GWML) and East Coast Main Line (ECML) for the Government’s InterCity Express Programme (IEP).

Utilising SES’ integrated supply chain and offsite manufacturing facility, Prism meant they were able to offer a turn-key approach based on a responsive and adaptive technical authority, which underpinned Hitachi’s ambitious vision for the development. Prism removed 10,000hrs from site with its bespoke solutions (which included bespoke modules, invertor frames, skids and leak test facility).

This project presented a huge opportunity for people and businesses across the North East region creating hundreds of jobs on site with 95% of the workforce contractors being employed from within a 50 mile radius to the facility.

This state-of-the-art facility has showcased the very best in UK construction and engineering and handed over on time and on budget.

Darren Cumner, Plant Manager, Hitachi Rail Europe commented:

“We had a very professional team constructing our state-of-the-art rail vehicle manufacturing facility; the high standards achieved meant that we finished the build ahead of plan with the perfect foundation for Hitachi Rail to manufacture world-class rolling stock solutions.”

Other Case Studies

Leeds students benefit from fantastic £80m creative arts building

Leading engineering specialist, SES Engineering Services (SES), has announced the completion of MEP works on the impressive Creative Arts building in Leeds City Centre, which has a development value of £80m.

Teesside Energy Centre

SES Engineering Services (SES) was appointed to design, install and commission the mechanical, electrical and plumbing (MEP) services on Teesside Energy Centre which was constructed by a consortium between Lagan Construction and Babcock & Wilcox Vølund (BWV).

Akzo Nobel ECG Building

SES was pleased to be appointed to work closely with construction, infrastructure and support services company Robertson CE on this important project, with responsibility for mechanical and electrical services.