Utilising world-leading offsite manufacturing and technical innovations SES Engineering Services (SES) marked the culmination of its mechanical and engineering (M&E) contract on a 67-acre landmark development at one of the most significant new parts of central London. Working alongside long-standing client’s main contractor Carillion and developer Argent, SES successfully provided full design and build M&E services to more than 255 apartments across 13 floors of The Plimsoll Building at King’s Cross and two new schools including the Frank Barnes School for children who are hard of hearing.

The Plimsoll Building or P1 as it is better known is a showcase for the latest offsite manufacturing techniques and has attracted widespread praise from the engineering industry. Through the use of pioneering and award-winning BIM2MOSAIC technology we were able to develop our revolutionary ‘box of wonders’ – essentially a utility cupboard, one for each of the apartments which incorporated all essential mechanical and electrical plant and equipment.

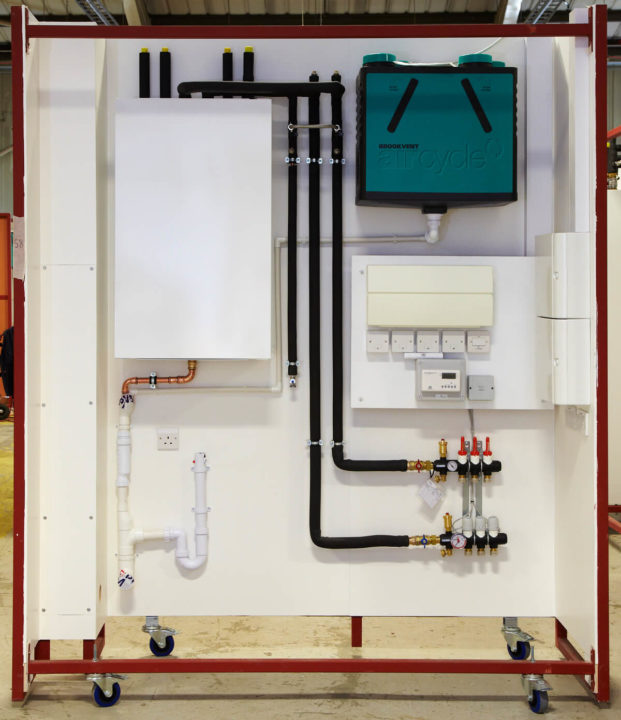

These installations – including a heat interface unit, MVHR units, underfloor heating manifolds, consumer unit, BT Home Hub and spacial planning for all white goods which represented a major efficiency and safety innovation. Created off site, these units would otherwise have required multiple trades on site working in a congested area, representing a major logistical and health and safety issue.

By modularising these services at Prism, we were able to dramatically reduce the number of man hours on site by 14,600 ensuring the end result provided us with a project that was delivered on time.

As a result of a positive SES project performance we secured a further two phases on the King’s Cross development for Gasholders London and the S2 Building projects.

Other Case Studies

GSK Aseptic Manufacturing Facility - Q Block

SES worked to a detailed schedule of works to install all mechanical and electrical (M&E) building services, ensuring that there was minimum disruption to the live manufacturing site which completed in January 2020.

Akzo Nobel ECG Building

SES was pleased to be appointed to work closely with construction, infrastructure and support services company Robertson CE on this important project, with responsibility for mechanical and electrical services.

West New Build Police Headquarters

SES Engineering Services (SES) working collaboratively with principal contractor Willmott Dixon created a new, state-of-the-art headquarters for Lancashire Constabulary’s West Division in Blackpool.