The official launch of the £38m National Biologics Manufacturing Centre in Darlington which is developed and managed by the Centre for Process Innovation took place in September 2015. This new centre provides companies with open access facilities and expertise to help them develop, prove and commercialise new and improved processes and technologies for biologics manufacture.

Plans to build the new centre were announced in 2012 as a result of the UK government’s Strategy for UK Life Sciences, which was launched in 2011 to strengthen the life-science sector. The strategy outlined a vision for the UK to be a global leader in the life science sector. The £38m investment was made by the Department for Business Innovation and Skills through InnovateUK.

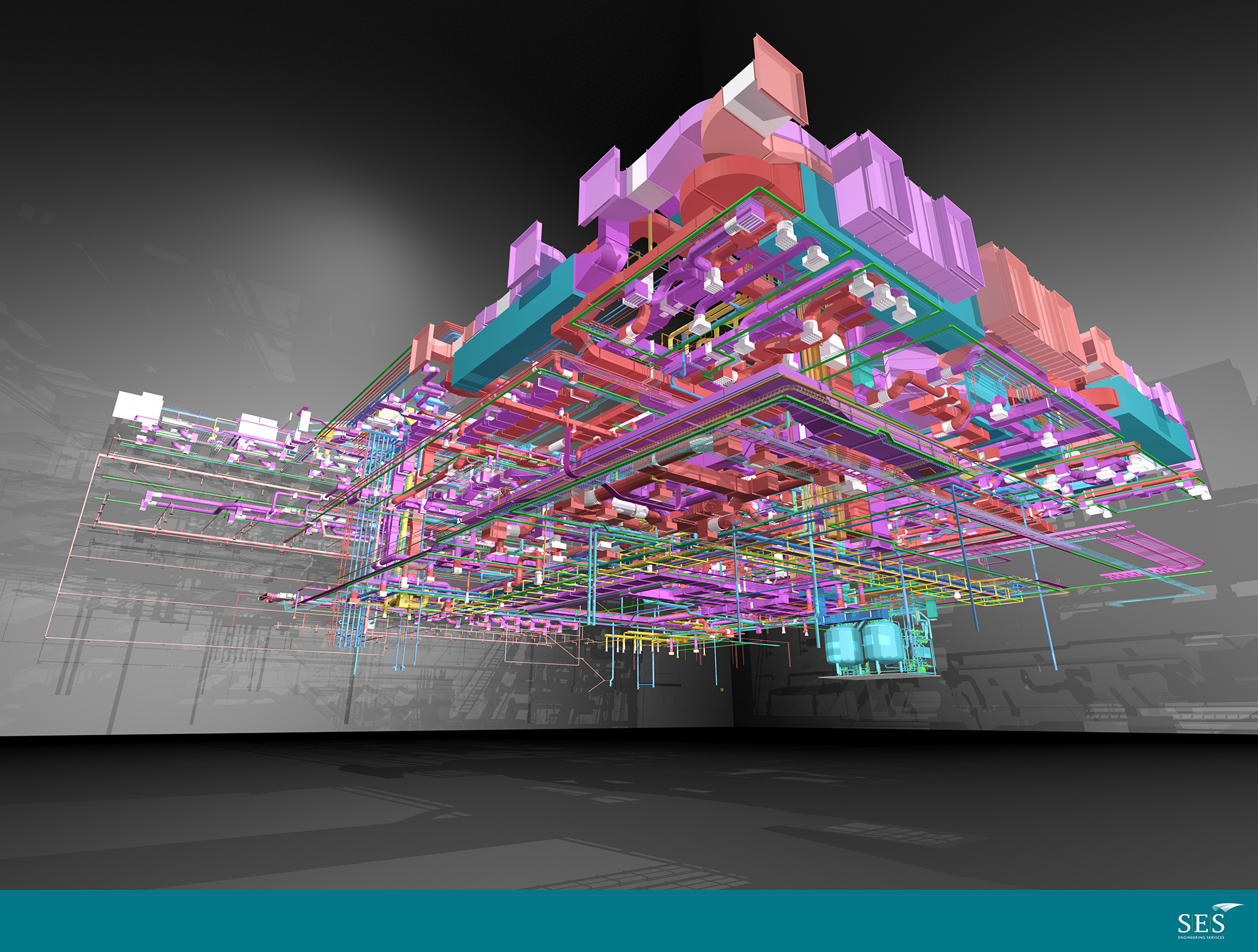

SES Engineering Services (SES) was appointed to provide M&E services to this highly complex and technical build to deliver a new build three-storey laboratory facility with both HVAC and Process Installations providing flexible testing facilities for new process and technology development.

Demonstrating our technical authority on the project the site team, Prism and the BIM team worked tirelessly to deliver an inspiring world-class building with much of the build being built off site which allowed thousands of man hours to be taken off the programme critical path also minimising on-road transportation and site congestion.

In 2015, the project team were Highly Commended at the Constructing Excellence in the North East Awards in the Integration and Collaborative Working category.

CENE award achieved

saved by using Prism

used within a 50 mile radius

build value

Other Case Studies

Ronald Ross Building Phase 1, Institute of Infection and Global Health (Apex I)

SES Engineering Services (SES) was appointed as the Mechanical and Electrical (M&E) services provider for the development of the first phase of the Ronald Ross Building for the University of Liverpool.

EDGE

Due to complete in 2026, the landmark commercial office development in London Bridge for EDGE Technologies is set to be London's most sustainable office building, setting new standards for intelligent office spaces in the UK.

The Defence and National Rehabilitation Centre (DNRC)

Handed over by Prince William, the Duke of Cambridge and Prime Minister, Theresa May in June 2018, the DNRC will be operated by the Ministry of Defence when it opens later this year.